Infosheet diamond burnishing tools

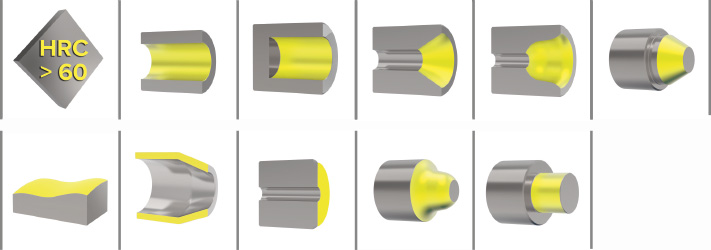

Possible machining contours

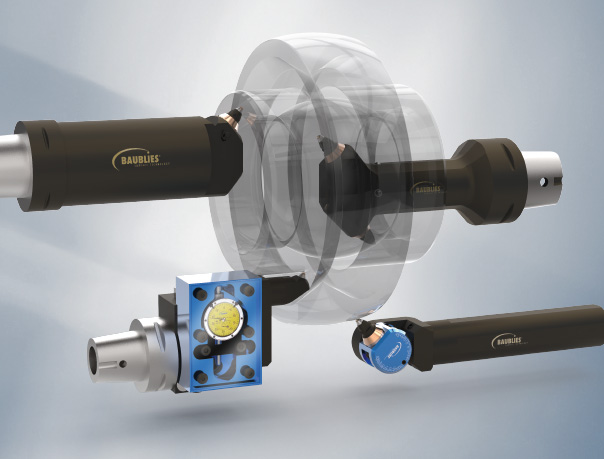

DIAMOND-BURNISHING TOOLS: FOR HIGHEST PRECISION

Diamond-burnishing tools expand the range of applications of roller burnishing technology, as even hardened materials up to approximately 60 HRC can be roller burnished.

In the process, a high-precision, micropolished diamond glides over the surface. As soon as the yield point of the material is exceeded, the profile peaks of the workpiece surface flow into the adjacent recesses in the µm range.

Compared to the machining by means of rollers, the contact area between the workpiece and the diamond is much smaller. Therefore, plastic cold working with a reduced influence of force can take place. Baublies diamond roller burnishing tools advance into hardness and diameter areas in which conventional roller burnishing tools cannot be used due to the workpiece characteristics or geometry. With diamond-burnishing tools, all contours – internally and externally – can be roller-burnished and deep-rolled.

ADVANTAGES

- Maximum process reliability

- Top surface qualities

- Harder outer layers

- Smoothing of hardened components

- No need for additional equipment such as hydraulic units

- Increase in fatigue strength

- Larger contact area ratios due to plateau formation

- Higher surface resistance to wear and corrosion

- Expanding of material fatigue limits

- Reduced sliding friction coefficients

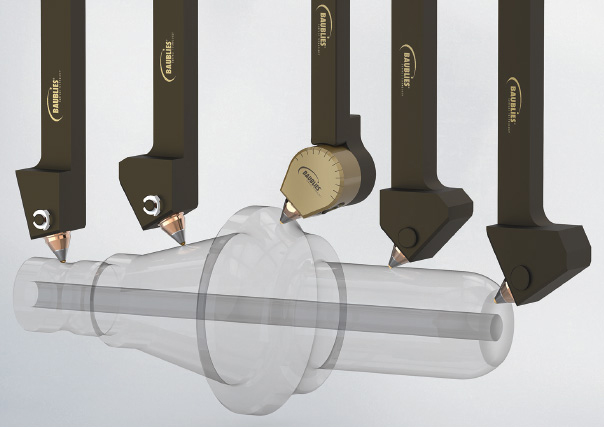

COLIBRI: PERFECT FINISH FOR SOPHISTICATED WORKPIECES

Small, fine and in excellent Baublies quality: these are the new burnishing tools that we have developed especially for filigree applications. We have optimized our many years of know-how in diamond burnishing for the machining of small precision parts and thin-walled workpieces in a compact form.

RANGE OF APPLICATION OF THE COLIBRI SERIES

Diamond burnishing tools from the COLIBRI series are always optimally suitable when the peak-to-valley height of filigree workpieces is to be minimized and at the same time the strength is to be increased.

Typical application areas are:

- Components for medical devices and the optical industry

- Connecting elements for aerospace and automotive technology

- As well as other compact precision parts in which surface quality plays a crucial role